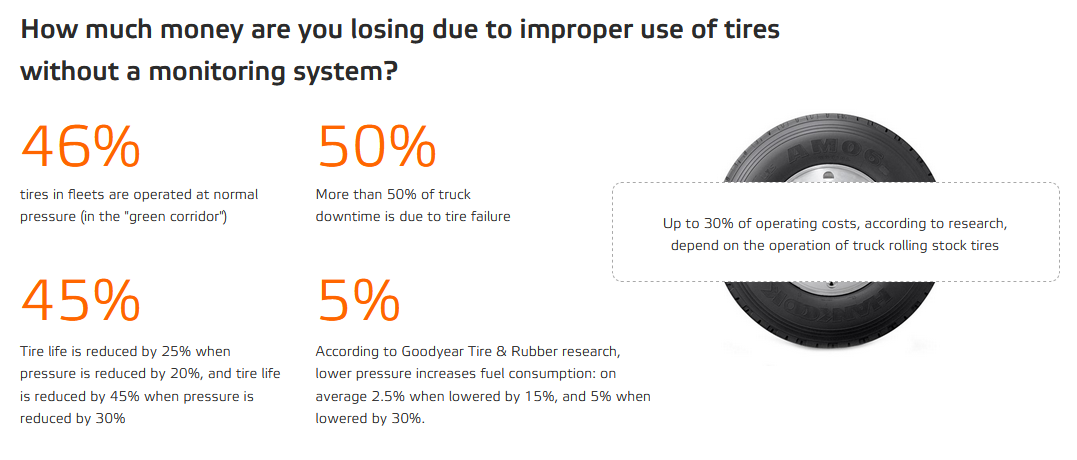

Transportation companies have high financial costs related to fuel control, spare parts, drivers and logistics, and less attention is paid to the operation of tires. That is, until the tires fail at the worst possible time. And their service life can be easily extended with pressure and temperature control systems.

While driving, the air pressure in the tires is constantly changing. This is not only due to physical damage to the tire, but also due to temperature variations in different weather conditions and the speed of the vehicle. In the case of quarry equipment and work in inaccessible terrain, you need to take into account the harsh operating conditions of mining operations - poor visibility, terrain, low temperatures, round-the-clock operation, etc.

If the pressure rises or falls, the tire overheats and irreversible destruction occurs. It is not practical to do control “manually” - on the road you will have to stop often and take measurements with a pressure gauge. And this does not always allow you to trace the fault. For a more effective solution, tire pressure and temperature control systems have been developed.

If the pressure rises or falls, the tire overheats and irreversible destruction occurs. It is not practical to do control “manually” - on the road you will have to stop often and take measurements with a pressure gauge. And this does not always allow you to trace the fault. For a more effective solution, tire pressure and temperature control systems have been developed.

How the solution works

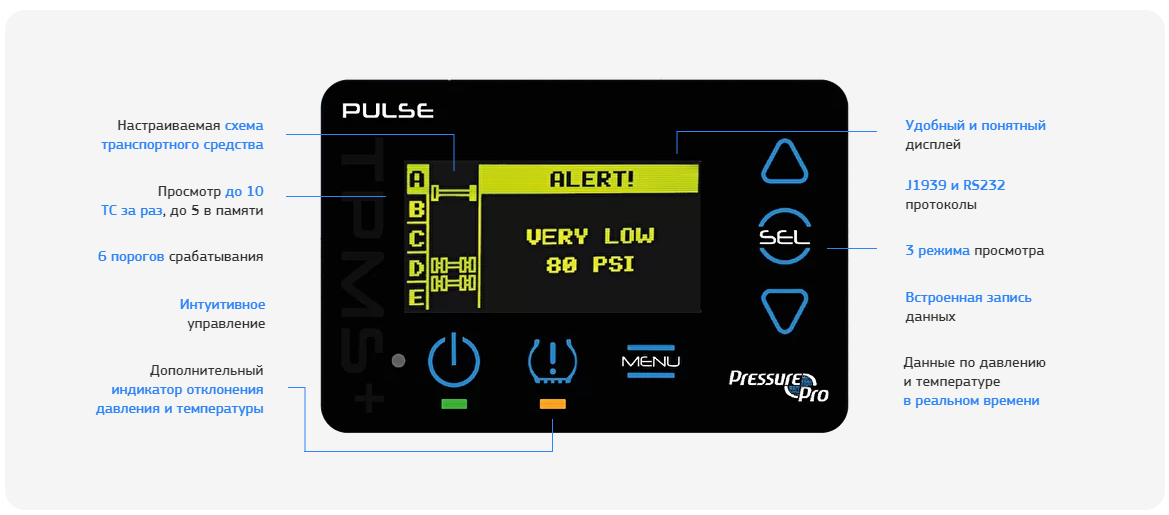

Online tire pressure and temperature monitoring system is a sealed, wireless, shockproof sensor with a built-in power cell installed on the tire valve of the vehicle. The system regularly measures tire pressure and temperature and transmits the data to the display in the driver's cab every 7 seconds. During installation, threshold values are set; if the values exceed the limits, the device signals the driver and the fleet dispatcher to the MONTRANS ONLINE monitoring system. This makes it possible to thoroughly and correctly assess the operation to protect them from accidents.

Benefits of use

A tire pressure and temperature monitoring system solves at least four issues.

- Firstly, it ensures safety on the road and during vehicle operation at the site. It signals changes in parameters in time, and also improves the balance of the vehicle according to the principle of “different pressure”, eliminating so-called “bias”.

- Secondly, it significantly improves machine performance: the average mileage and tire life before tread wear becomes higher. This is a direct consequence of the grip contact pattern: the more symmetrical it is, the longer the tire will last.

- Third, it reduces downtime due to unexpected tire repair or replacement, which has a positive impact on the financial component of the fleet and the implementation of the work schedule.

- Fourth, it is a solution to an environmental problem. Along with the extended service life, the tire is given the opportunity to be remanufactured and returned to service. The number of used tires, which are hazard class 4 waste, is reduced. And when tire pressure deviates, the vehicle uses additional fuel, and at the same time the emissions into the atmosphere.

A tire pressure and temperature monitoring system solves at least four issues.

- Firstly, it ensures safety on the road and during vehicle operation at the site. It signals changes in parameters in time, and also improves the balance of the vehicle according to the principle of “different pressure”, eliminating so-called “bias”.

- Secondly, it significantly improves machine performance: the average mileage and tire life before tread wear becomes higher. This is a direct consequence of the grip contact pattern: the more symmetrical it is, the longer the tire will last.

- Third, it reduces downtime due to unexpected tire repair or replacement, which has a positive impact on the financial component of the fleet and the implementation of the work schedule.

- Fourth, it is a solution to an environmental problem. Along with the extended service life, the tire is given the opportunity to be remanufactured and returned to service. The number of used tires, which are hazard class 4 waste, is reduced. And when tire pressure deviates, the vehicle uses additional fuel, and at the same time the emissions into the atmosphere.

Pressure monitoring systems use less fuel, which is extremely important given the steady rise in gasoline prices. Of course, tires do not fall into disrepair every day, but it is much more efficient to receive real-time data on possible malfunctions in order to be proactive and significantly reduce the financial costs of your company.