20+

Years of experience

11

Branch offices

25000+

Facilities under service

22

Regions of operation

Our social media

India:

Uzbekistan:

Additional sensors

Wide range of ready-made solutions

In-house production

The main parameters of vehicle monitoring are: location, distance traveled and fuel consumption. But for a complete picture of the vehicles' performance, a number of other indicators are required.

Installation of additional sensors allows you to achieve full transparency in the activities of the fleet and receive analytical reports on the efficiency of the enterprise.

Installation of additional sensors allows you to achieve full transparency in the activities of the fleet and receive analytical reports on the efficiency of the enterprise.

Long warranty period

Speed limiting devices are an effective tool to ensure safety on the road. ADR ("The European Agreement concerning the International Carriage of Dangerous Goods by Road.") is an international agreement adopted in Europe more than 50 years ago. The document defines the rules of transportation of dangerous goods on the territory of European countries.

In Russia, the transportation of this type of cargo is carried out in accordance with Regulations relating to the transport of dangerous goods.

According to foreign and Russian standards, speed limiting devices must be installed on vehicles carrying dangerous goods weighing more than 3.5 tons, as well as on vehicles for the transportation of children. For example, the limit for trucks is 90 km/hour, and for children's buses - 60 km/h.

The principle of operation: the device reduces the fuel supply until the speed of the car decreases to the set value. Traffic police officers can check the presence of the SLD, its compliance with the requirements of the regulations, sealing and certification. MONTRANS specialists install high-quality equipment, which will save carriers from many problems in the future.

In Russia, the transportation of this type of cargo is carried out in accordance with Regulations relating to the transport of dangerous goods.

According to foreign and Russian standards, speed limiting devices must be installed on vehicles carrying dangerous goods weighing more than 3.5 tons, as well as on vehicles for the transportation of children. For example, the limit for trucks is 90 km/hour, and for children's buses - 60 km/h.

The principle of operation: the device reduces the fuel supply until the speed of the car decreases to the set value. Traffic police officers can check the presence of the SLD, its compliance with the requirements of the regulations, sealing and certification. MONTRANS specialists install high-quality equipment, which will save carriers from many problems in the future.

Speed limiting device (SLD)

On-board weight control systems are one of the most modern ways of weighing cargo without using checkweighers and other equipment with similar functionality.

MONTRANS axle load sensors help to: simplify weighing of cargo during loading and unloading operations, exclude cargo "losses" during transportation, exclude "left" trips, exclude transportation of unaccounted cargo, prevent increased wear and breakage of parts due to exceeding the permissible weight.

Axle load monitoring can be used on all types of suspensions: mechanical (spring), hydraulic and pneumatic. Correct axle load distribution can avoid large fines. For example, under current legislation, a legal entity, including sole proprietorships, can be fined up to 500,000 rubles for exceeding the authorized weight by 50%.

MONTRANS axle load sensors help to: simplify weighing of cargo during loading and unloading operations, exclude cargo "losses" during transportation, exclude "left" trips, exclude transportation of unaccounted cargo, prevent increased wear and breakage of parts due to exceeding the permissible weight.

Axle load monitoring can be used on all types of suspensions: mechanical (spring), hydraulic and pneumatic. Correct axle load distribution can avoid large fines. For example, under current legislation, a legal entity, including sole proprietorships, can be fined up to 500,000 rubles for exceeding the authorized weight by 50%.

Axle load sensor

The hour monitor is used to monitor the status (running/stopping) of engines and other mechanisms.

The device cannot be "cheated". The uniqueness of the Motor Hour Monitor is that vibration is a sign of operation. The sensor analyzes the amplitude-frequency characteristic of vibration of the started engine, and on the basis of this determines the fact of its operation.

The wireless sensor stores the received data on the operation/stop of the mechanism in its own non-volatile archive or transmits it to a satellite terminal. As part of the MONTRANS transportation monitoring and fuel control system, a solution has been developed that will make it possible to determine when machinery is idling and when it is under load.

The device cannot be "cheated". The uniqueness of the Motor Hour Monitor is that vibration is a sign of operation. The sensor analyzes the amplitude-frequency characteristic of vibration of the started engine, and on the basis of this determines the fact of its operation.

The wireless sensor stores the received data on the operation/stop of the mechanism in its own non-volatile archive or transmits it to a satellite terminal. As part of the MONTRANS transportation monitoring and fuel control system, a solution has been developed that will make it possible to determine when machinery is idling and when it is under load.

Motor hour monitoring sensor

One of the most important parameters in the transportation of perishable goods is the temperature inside the van.

The GLONASS sensor measures the temperature within the range from -55 to +80°C with high accuracy. This data, together with navigation information, is transmitted in real time via the GSM network to the MONTRANS cloud service.

The software continuously reads the parameters, providing extensive possibilities for remote monitoring.

The temperature in the isothermal chamber can be monitored simultaneously by: driver, dispatcher and company manager. If agreed, the customer can also monitor compliance with the rules of cargo transportation.

The GLONASS sensor measures the temperature within the range from -55 to +80°C with high accuracy. This data, together with navigation information, is transmitted in real time via the GSM network to the MONTRANS cloud service.

The software continuously reads the parameters, providing extensive possibilities for remote monitoring.

The temperature in the isothermal chamber can be monitored simultaneously by: driver, dispatcher and company manager. If agreed, the customer can also monitor compliance with the rules of cargo transportation.

Temperature sensor

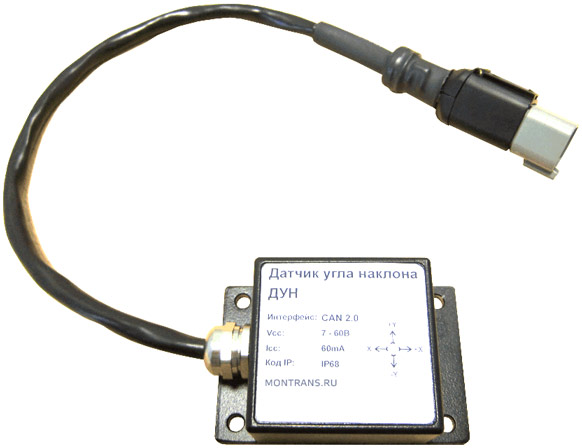

The controller constantly monitors roll and tilt angles and transmits data on the operation of special equipment to a cloud service. In addition, the use of such devices helps to significantly improve the safety of moving machinery operation.

For example, a sensor installed on the boom of an excavator or crane transmits information: how many manipulations have been made, the number of lifts, the duration of work and the time of stops.

The controller on the dump truck platform tracks the number of body lifts and the duration of loading and unloading.

The dispatcher of the company will always know: where, when and how long the equipment worked. The range of measured value from 0 to 180 degrees in three axes of coordinates. Tilt angle sensors work at temperatures from -60 to +85 ° C.

For example, a sensor installed on the boom of an excavator or crane transmits information: how many manipulations have been made, the number of lifts, the duration of work and the time of stops.

The controller on the dump truck platform tracks the number of body lifts and the duration of loading and unloading.

The dispatcher of the company will always know: where, when and how long the equipment worked. The range of measured value from 0 to 180 degrees in three axes of coordinates. Tilt angle sensors work at temperatures from -60 to +85 ° C.

Sensor for actuator operation

A very important indicator in a refrigerated truck monitoring system is the time and place of door opening.

The opening of the isothermal chamber gives an understanding of where and how long the loading and unloading took place. Therefore, to get more accurate information about transportation conditions, sensors for door opening and closing are installed together with temperature sensors.

Door monitoring helps to keep the body at the set temperature and to deliver the goods in the right quality and without losses.

The opening of the isothermal chamber gives an understanding of where and how long the loading and unloading took place. Therefore, to get more accurate information about transportation conditions, sensors for door opening and closing are installed together with temperature sensors.

Door monitoring helps to keep the body at the set temperature and to deliver the goods in the right quality and without losses.

Door open/close sensor

Check if MONTRANS digital fleet management is the right fit

Please provide your contact details to complete the request. Our manager will get in touch with you soon.