20+

Years of experience

11

Branch offices

25000+

Facilities under service

22

Regions of operation

Our social media

India:

Uzbekistan:

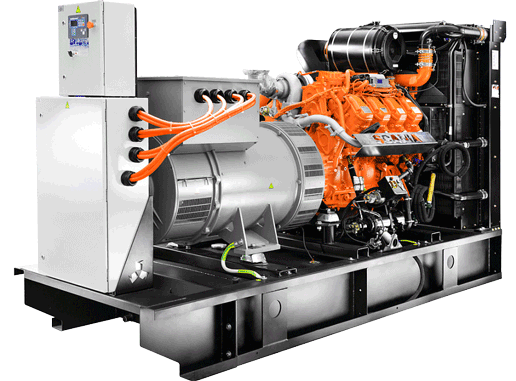

REMOTE CONTROL OF DGU AND DPP

Remote control of DGU and DPP is carried out using special monitoring and control systems that allow you to quickly receive information about the state of the installation and manage it remotely. This can be useful when the DGU or DPP is located at remote sites or when the operator cannot be near the plant.

Remote monitoring and control system for diesel generators and diesel power plants.

/

/

/

System scalability

Remote control DGU

Online statistics for many parameters

GPS\GLONASS terminal

Universal Automation Controller

Digital fuel gauge

Fuel volume indicator

Engine hour sensor with acoustic sensor

Engine Lock Relay

The system allows to build the process of remote On-line monitoring of operational parameters of DGU, namely:

Provides control over the output power in units time to determine the effectiveness of the use of DGU in operation

Prevent failures and breakdowns of DGU. In order to avoid burnout of the voltage regulator and power generators, display in On-line mode the parameters responsible for the phase load distribution. (phase powers, phase currents, phase voltage), to receive and display in real time the parameters of the occurred overload of the DGU more than 80% of the rated power.

Receive timely notifications of accidents in the operation of the DGU (Emergency stop, power surge, overheating of the generator winding)

Maintain control over the timeliness of maintenance and repair

Increase the efficiency of using diesel generator sets and diesel power plants

Receive and display in On-line mode the parameters responsible for the total operating time, the total amount of electricity issued in kW (active and reactive power)

Automate the process of perception of dependence on the operation of the DGU with a load of less than 50% of the maximum power.

•

•

•

•

•

•

•

Decryption of parameters

An example of a report on displaying the operating parameters of a diesel generator set

Q - reactive power

P - active power

i1,i2,i3 - phase currents

u1n,u2n,u3n - phase voltages

u12,u23,u31 - linear voltages

P - active power

i1,i2,i3 - phase currents

u1n,u2n,u3n - phase voltages

u12,u23,u31 - linear voltages

Monitoring of diesel generator sets provides the possibility of remote control and management of the backup power supply system. Using this solution, you will be able to control the DGU from anywhere in the world, analyze data on fuel consumption and the operation of additional equipment, and quickly respond to emergency situations.

S - full power

PF - Power Factor (PF) is a complex indicator. It characterizes the linear and non-linear distortions of the voltage and current waveform of the mains, which are caused by the influence of the load (eg UPS). In order to calculate PF, it is necessary to compare the absorbed load of active power and the total load.

PF - Power Factor (PF) is a complex indicator. It characterizes the linear and non-linear distortions of the voltage and current waveform of the mains, which are caused by the influence of the load (eg UPS). In order to calculate PF, it is necessary to compare the absorbed load of active power and the total load.

•

An example of tracking a failure in the operation of a generator set

Each time before turning off the diesel power plant, there is a load surge (uneven in phases), the voltage regulator tries to compensate for the inequality, raises the voltage in phase L3 above the norm (252 V) and turns it off in an accident.

•

Received data via Modbus in Omnicomm Online

Fuel consumption

ICE revolutions

ICE temperature

Oil pressure

Phase Voltage

Generator Frequency

ICE revolutions

ICE temperature

Oil pressure

Phase Voltage

Generator Frequency

Fuel consumption can be monitored both via the CAN bus and using digital fuel level sensors

•

•

•

•

•

•

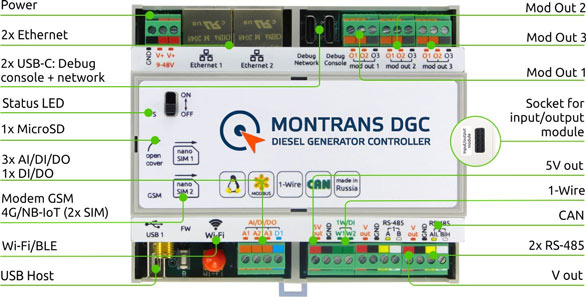

Diesel Generator Controller

Universal Automation Controller - MONTRANS DGC

Additionally, the diesel generator controller can be equipped with various expansion modules. The controller is programmed based on the model of the DGS control controllers and also collects and transmits data on the technological and operational parameters of the DGS to the platform. From the control controller, it is possible to receive data both on the mechanical part (ICE) and on the electrical part (Generator)

•

As a result of the implementation of the monitoring system, the owners of DGU receive:

The introduction of the MONTRANS telematics system gives the client the opportunity to remotely control the operation of the diesel generator. The application is installed on the customer's smartphone or computer, which allows not only to receive information about the state of the DPP, but also to start and stop the engine. In the settings, alarm events are set, when triggered, a message is sent to the client. In addition, the monitoring system generates reports on changes in various parameters of the diesel generator set.

— remote operational control of the state and parameters of the power plant

— blocking the engine

— exclusion of theft of fuel and lubricants

— exclusion of misuse of mobile diesel generators

— elimination of equipment downtime

— reduction of fuel purchase costs by up to 50%

— improving the safety of the power plant

— blocking the engine

— exclusion of theft of fuel and lubricants

— exclusion of misuse of mobile diesel generators

— elimination of equipment downtime

— reduction of fuel purchase costs by up to 50%

— improving the safety of the power plant