20+

Years of experience

11

Branch offices

25000+

Facilities under service

22

Regions of operation

Our social media

India:

Uzbekistan:

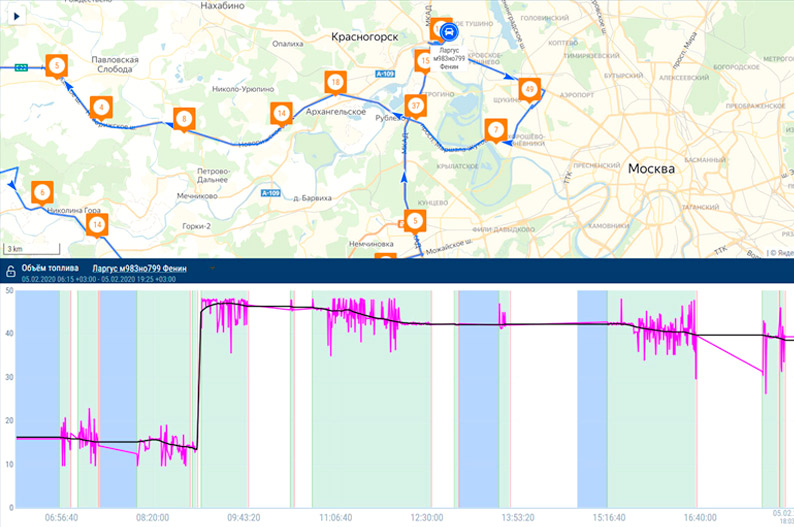

Connection to OEM fuel level sensor

In most cases, the measurement error of the standard fuel dispenser does not allow to obtain data suitable for accurate fuel accounting when writing off fuel or when calculating the average consumption and recording refuelings

Accuracy of readings

The practice of using the OEM gauge to monitor fuel consumption as well as refueling - split in two. In some cases satisfactory readings were received, acceptable for realization of necessary control. However, in most cases the readings were extremely unstable, with high amplitude of fluctuations and it was not reasonable to use them for control. This is primarily due to the poor quality of the sensor itself and the lack of pre-filtering of data from the float itself. Also the degree of wear of the vehicle itself has a huge impact.

We recommend to try only in case of complete absence of technical possibility to use other means of fuel level and consumption control. It is possible to determine the accuracy of readings only by trying to connect, unfortunately there are no other ways.

We recommend to try only in case of complete absence of technical possibility to use other means of fuel level and consumption control. It is possible to determine the accuracy of readings only by trying to connect, unfortunately there are no other ways.

Strong fuel fluctuations

Low price (or rather complete absence of costs for purchasing additional equipment)

Lots of false refills and drains

Advantages of the sensor

Disadvantages of the sensor

Significant error in the accuracy of readings

Dead zones in the measuring range

Due to the large error of operation of standard fuel sensors, for correct control of fuel consumption we recommend to use other equipment options